Gear manufacturing is a huge industry, and it’s one that’s growing rapidly. In fact, it’s expected to grow by as much as 20% over the next ten years. If you want to be part of this trend, you need to have a gear manufacturing business that’s fully functioning. And that means having the right tools and equipment.

Unfortunately, many businesses don’t realize this until it’s too late. That’s why it’s important to have a team of experts on your side who can help you get set up the right way from the start. We operate a fully functioning gear manufacturing business, and we want to help you do the same. Contact us today for more information about how we can help you reach your goals.

Gear manufacturing: What it is and what it does

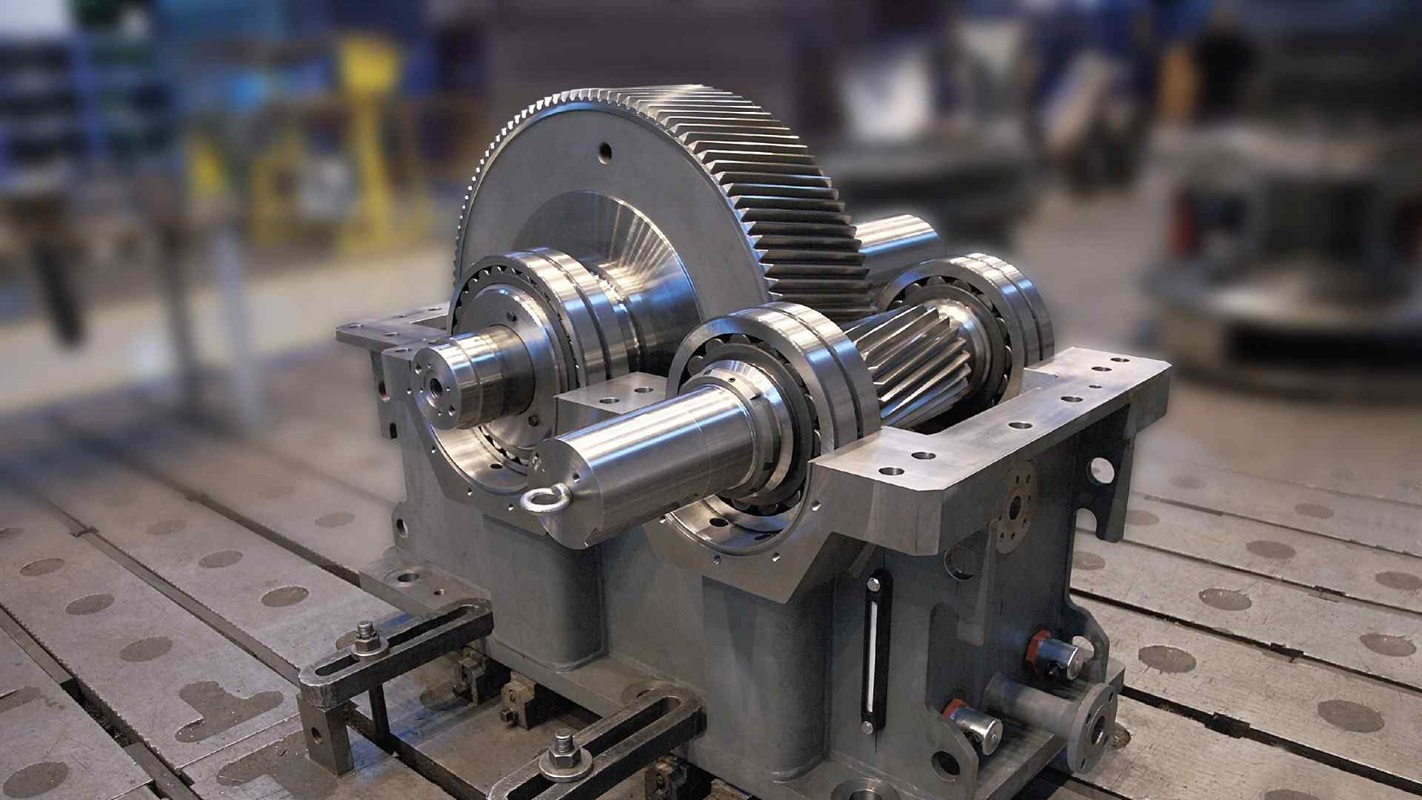

Gear manufacturing is the process of creating gears, chains, shafts, and other mechanical components by machining or stamping. Gear manufacturing can be divided into two main categories: small-scale gear production and large-scale gear production. Small-scale gear production involves the machining of individual gears while large-scale gear production involves the assembly of numerous gears into larger assemblies.

The main types of gears that are manufactured include fixedgear and helical gears. Fixedgear gears are between 3 and 50 teeth in size and are used in applications that require high precision or speed. Helical gears are between 50 and 1,500 teeth in size and are used in applications that require low noise or torque ratings. Gear manufacturers also produce hybrids such as spur/ratchet gears that combine the advantages of both fixedgear and helical gears

Gear manufacturing: The different steps involved

Gear manufacturing is a process that involves taking a raw piece of metal and creating something that can move efficiently. The different steps involved in gear manufacturing are: drawing the design, machining the parts, assemblying the gears, and testing.

When designing gear for use in industrial applications, engineers must take into account many factors, including the type of load the gear will be subjected to and the speed at which it will need to operate. Machining centers use machines with precise cutting tools to create precision gears. Assemblers then fit the gears together and test them to make sure they work properly. Gears that pass these tests are put into use.

Gear manufacturing: How it works

There are a few basic steps in gear manufacturing. The first step is to design the gear. Gear designers use CAD software to create a 3D representation of the gears and other parts of the product. They also use simulations to determine how the gears will work together.

The second step is to build the gears. Gear manufacturers use CNC machining techniques to create the parts. This involves cutting out the pieces with precise angles and shapes. The pieces are then assembled using special tools and machines.

The final step is testing and quality control. Gear manufacturers must ensure that the gears are strong and fit properly into their products. They also need to make sure that the products are safe for users.

We hope that this article on gear manufacturing has been helpful. Whether you are a small business owner looking to start up your own gear manufacturing company or an individual who is in need of quality gears but doesn’t know where to turn, our guide should provide you with the information you need. With the help of our team, getting started in gear manufacturing won’t be too difficult. Thanks for reading!