Do you know that Weighing Platform Scales could be the difference between making or losing money? Are you looking for the best platform scales to help your business grow? You are in the best place. In this guide, we will look at what platform scale is and how it helps your business make money better.

Read More: GUDID Services

What is a platform scale?

Platform scales are essential to any warehouse or industrial setting, as they provide a way to weigh materials while still in their containers. With the right platform scale, you can ensure that every container is weighed and recorded accurately, so there’s no chance of human error or misinterpretation.

Platform scales are also great for checking the weight of individual items. For instance, if you’re looking to sell items by weight, it’s important to know exactly how much each item weighs so you can price them appropriately. Platform scales are ideal because they’re easy to use and portable enough to fit in any warehouse setting.

Read More: barcode services

How do they work?

Weighing platform scale work by weighing the load on a platform and then calculating the weight of the load. The scale then gives you an accurate reading of the weight of the object on it. The way that these platform scales work is by having a spring and a balance beam inside them. The spring is attached to the bottom of the balance beam, allowing it to move up and down as more or less weight is added.

The spring also has a mechanism that keeps it from moving too far in either direction. This allows for reading accuracy when heavy items are placed on top of it.

Why are they used?

Platform scales are used to weigh large or heavy items. They are made of a platform, often made from steel, and the scale itself. The scale is usually a mechanical device that includes a counterweight, which allows you to use it even if there is no power source nearby. These scales are most commonly used in factories and warehouses, where they can weigh large amounts of materials and products.

Types of platform scales

There are several different types of platform scales:

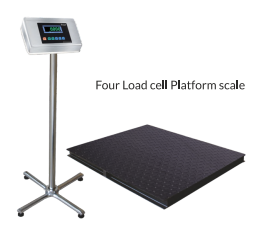

1. Load cell platform scale:

This scale has sensors on the bottom of the platform that measures how much pressure is being applied. This helps ensure that you get an accurate weight measurement as long as there’s no shifting or movement on the scale itself.

2. Digital platform scale:

This scale uses sensors on the bottom of the platform to detect weight, but it also uses an LCD screen to display weights in digital form rather than analog. This allows for quick reading of weights and easy use by those who aren’t used to using analog scales.

3. Analog platform scale:

This type of platform scale has only one measurement—the weight—and shows this measurement through a dial that rotates around its center point until it reaches zero. At this point, it resets to zero (or starts over if you’ve added more weight).

How to clean platform scales?

If you have a platform scale, you may want to clean it regularly. This will prevent the buildup of dirt, dust, and grime that can affect its accuracy. Here’s how to do it:

- Unplug the platform scale from its power source, then remove all objects from the surface of the scale.

- Wipe down the surface with a damp cloth or sponge, careful not to get water into any openings on the scale itself.

- Dry off any moisture with another cloth or paper towel before turning it back on again; leaving moisture on can cause rusting inside those areas, which will affect performance over time and damage any electrical components there too!

Benefits of weighing platform scale

Platform scales are the most common type of industrial Weighing scale used in various industrial settings. The benefits of weighing Tabletop Weighing scales include the following:

Ease of use

Weighing platform scales are easy to use, as they require no power source. They can be used right away and don’t require installation or maintenance.

Accuracy

Weighing platform scales provide accurate measurements. They feature a sensitive, highly accurate load cell that accurately measures an object’s weight when placed on top of the scale.

Versatility

Weighing platform scales are versatile enough to be used in most industries, from agriculture to manufacturing. They’re also suitable for use in homes and offices, where they can help keep records of home inventory or track how much weight you’ve lost over time.

Portable

Weighing platform scales are portable and easy to store away when not in use. This is especially useful if you need to move them around often or your office space isn’t very large.

What are the factors on which platform scales vary?

A platform scale is a device that measures the weight of people and goods and their height. Platform scales are widely used in the medical, food, and beverage industries and for weighing livestock.

The factors on which platform scales vary include:

– The type of load to be measured.

– The range of capacity that the scale must be able to handle.

– The accuracy level required from the scale.

Type of platform scales

There are many different platform weighing scales, and they all have a unique construction.

The most common type of platform scale is the “traditional design“ which consists of a platform that can be moved up or down by the weight of the load. The weight is measured by force required to move the load against gravity. This is accomplished using a tensioned spring system to push against one side of the scale while a weighted counterbalance pushes against the other.

The second platform scale type is called an “inclined plane“ type. This type uses two parallel planes for weighing purposes. The upper plane is usually made out of wood and has grooves cut into its surface so that it can hold weights in place without them sliding off during use; these grooves form what looks like miniature steps, as seen from above, to make sure that each piece is secured properly before moving upward again once finished with loading/unloading onto/off from this particular side.

The third type is called a “balanced beam“ style which uses two perpendicular beams: one long beam atop another shorter one; each side has its counterweight attached via pulleys at either end, which allows for easier movement up/downward and side-to-side; the use of counterweights allows for easier movement than with a single beam and also ensures that the load on the surface remains balanced at all times to prevent tipping over.

Conclusion: Different platform scales can be used in commercial use, and they can be easily customized as per the need of the application.

There is still a market for the old-fashioned wooden scale. The advantages, however, of the steel platform scale? It truly is a tool that will last a lifetime. Other than some light maintenance and low-level engagement in routine maintenance tasks, steel platform scales require little more than to be used repeatedly.